Super Focusing Cameras

UPLUS ENGINEERINGDefing common sense for cosmetic inspections; a camera for inspection at an angle

Inspections once possible only by human eyes are now possible by using our Super Focusing Camera

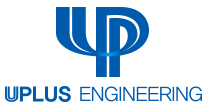

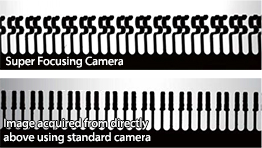

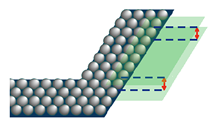

When capturing an image at an angle with a standard camera in the way a visual inspection is conducted, the captured image is only partially in focus and has perspective. It is therefore not suitable for inspection. The Super Focusing Camera solves this problem. In addition to realizing high-accuracy inspections, it contributes to the reduction of inspection-site costs.

Target Models

VTV-9000ST VTV-9000miniR VTV-9000mini

Three features only possible with the Super Focusing Camera

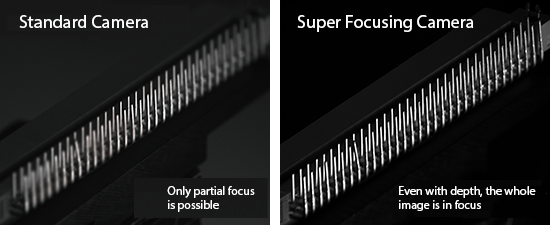

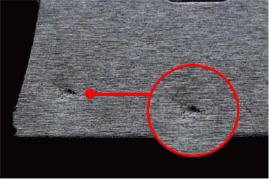

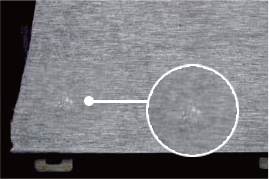

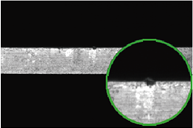

1. Defects such as scratches or dents can be seen more clearly

Some flaws or surface asperities might be less visible when captured from above. Capturing the image at an angle can make the flaws or surface asperities more visible.

Cast a shadow with a regular

reflection light for higher contrast.

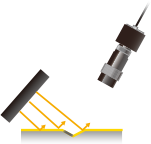

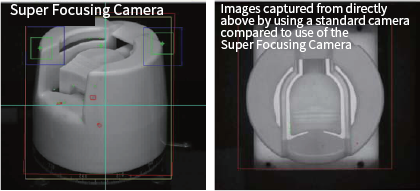

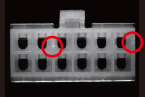

2. Sections that are not visible when an image is captured from directly above can now be inspected

Complex shapes might not be inspectable when using a camera from above, but using a camera at an angle can make issues obvious. This makesto the capture of satisfactory images of the area to be inspected possible.

<Terminal inspection of stamping parts>

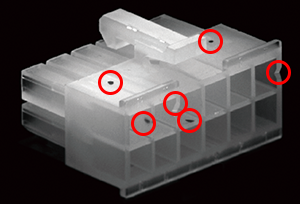

3. Images can be captured simultaneously from 3 sides

There is no need to prepare the same number of cameras and lightings as the number of inspected sides. Instead, one high-quality image that showing three sides can be captured. As a result, inspections are feasible with less cameras and captured images, and the entire inspection project can be done faster and with reduced costs.

Details of stereo inspection

Improved flexibility in machine design

Inspection on all sides possible by rotating → Complicated and expensive mechanism not necessary

Inspection on all sides possible by rotating → Complicated and expensive mechanism not necessary

The Following is a list of Super Focusing Camera applications.

- Cubic inspections to simultaneously capture images of three sides of molded products

- TP and width inspections on press-fit terminals

- Gap inspections of connector mating parts

- Connector pin tip detection

- Large molding item inner wall scratch inspections

- Inspections on integrated resin molding on lead frames

- Robot alignment

Hardware Specifications

12MP Monochrome

| Models | Load resolution (pixel) |

Image transfer speed | External dimensions (W) x (H) x (D) |

||

|---|---|---|---|---|---|

| Standard mode | High-speed mode | ||||

| VTC-R120M0 S-Series |

4080 x 3000 | 67ms (15fps) |

19ms (54fps) |

35 x 35 x 40.7 mm | |

※가로로 스크롤 할 수 있습니다.

※가로로 스크롤 할 수 있습니다.

5MP Monochrome/Color

| Models | Load resolution (pixel) |

Image transfer speed | External dimensions (W) x (H) x (D) |

||

|---|---|---|---|---|---|

| Standard mode | High-speed mode | ||||

| VTC-D050M0 S-Series |

2448 x 2048 | 29ms (35fps) |

- | 35 x 35 x 40.7 mm | |

| VTC-D050C0 S-Series |

|||||

| VTC-R050M0 S-Series |

2448 x 2048 | 29ms (35fps) |

7.6ms (132fps) |

35 x 35 x 40.7 mm | |

| VTC-R050C0 S-Series |

|||||

※가로로 스크롤 할 수 있습니다.